Project Description

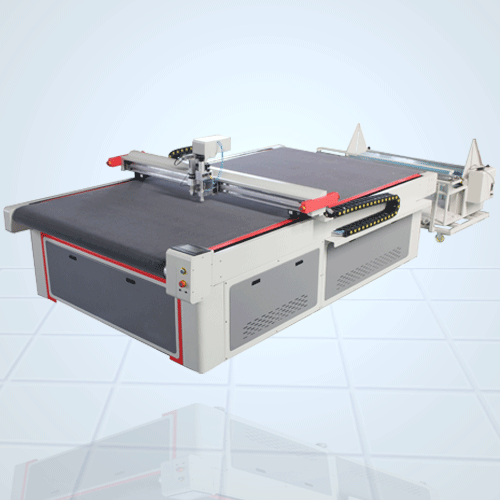

SFK automatic circular knife cnc cutting machine:

To learn more about the knife cnc cutting machine, please click on the “GET E-BOOK” button to download the following information:

-

SFK core components and functions

-

Product-related parameters

-

Detailed description of the product’s rapid processing

-

Cost and efficiency of operation

-

Detailed list of products

Overall description:The SFK automatic cutting machine is a high-speed, single (multilayer) automatic cutting system equipped with a circular knife (V-type cutting knife) that can accurately process leather, knitted fabric, woven fabric and composite fabrics.

SFK fully automatic circular cutter blanking machine features:

- Automatic processing, reduced dependence on personnel

The machine is equipped with an automatic cloth correction system. With the continuous cutting process, the cloth will be automatically returned and corrected. Continuous processing is fast and accurate. One person can operate the machine, reducing the cost of labor.

- Simple to install and easy to operate

Installation can be completed in half an hour. The SFK series comes with an electric control switch and gas path interface. The customer only needs to install the tool head to start the machine. Detailed video instructions provided by Amor demonstrate how to operate the control software. Even someone with no software experience will learn the operation in one day.

- Nesting done in one minute

The SFK series comes with a super discharging system. It takes only one minute to provide the customer with the perfect layout scheme. Manual discharging takes 30 to 40 minutes. Faster discharging increases the material utilization rate by more than 5%.

- Electronic management of the sample

The SFK series is computer-controlled. Customers can turn paper templates into electronic data and then digitally manage the data. During the cutting process, data is transmitted quickly. Operators no long have the difficult task of managing paper templates, and templates are no longer damaged by manual cutting.

- Automatic processing operation uses less space

The SFK series needs only 3mx6m for installation to complete the processing of materials, unlike the space needed for manual cutting.

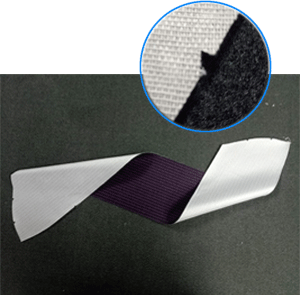

Able to process different materials:

The SFK series provides fast cutting for a variety of materials, including printed cloth, polyester cloth, non-woven cloth, leather and microfiber leather.

| Work Width | 1.6m/1.8m/2m (Customizable) |

| Work Length | 1.3m/2.5m (Customizable) |

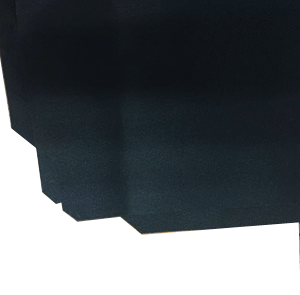

Platform with 4 mm-thick felt

imported from Italy:

4mm-thick felt platform with materials imported from Italy and EU certification guarantees quality and a longer service life.

Aerospace aluminum plate

adsorption platform:

Special aerospace aluminum materials ensure the flatness of the cutting platform and enhance the suction of the adsorbing felt platform. During the cutting, the processing materials are firmly fixed on the platform.