Rapid Manufacturing on Demand

Both Low & High Volume Moldings

Global delivery as fast as 2 weeks

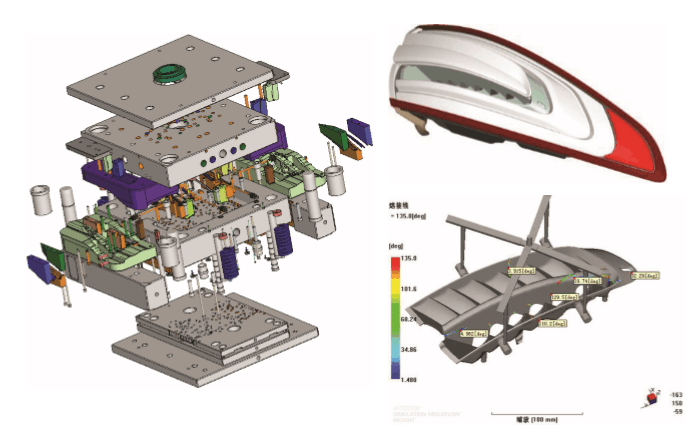

Rapid Tooling

Injection Molding

Injection Molding

From 50 to 10,000+ parts

Tooling in 15 days

Save up to 40% in cost

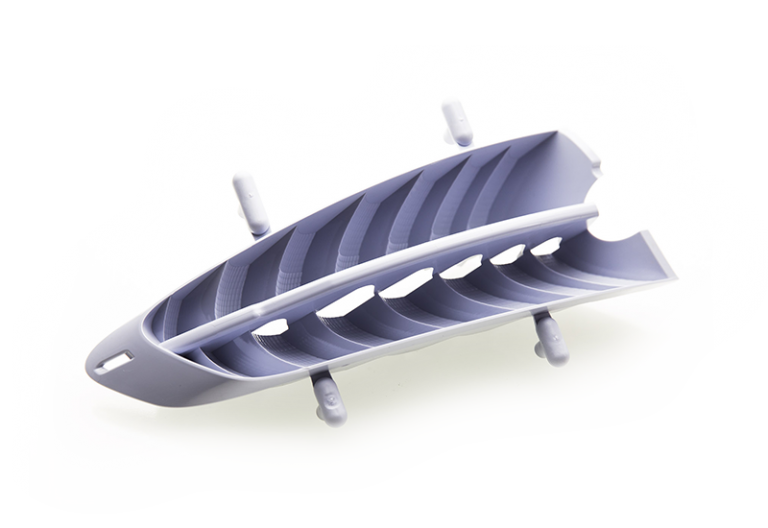

At 3ERP, we provide top quality custom rapid tooling & injection molding services. We do high quality aluminum tooling and hardened steel tooling for both short run and mass production needs, with quick turnaround times. You have the choice of a variety of different plastic resins and materials and can have your injection molded part in as little as 15 days.

Injection Molding Materials:

- POM

- PC/ABS

- PET

- PPS

- PP

- PS

- ABS

- PMMA/Acrylic

- Glass-Filled Nylon

- HDPE

- LDPE

- Nylon

- PBT

- PC

- PS/PPE

- TPE/TPV

Industries & Applications:

- Medical device industry

- Automotive industry

- Aerospace industry

- Consumer products industry

- Electronic

- Plastic prototypes

- End use parts

Color & Finishing:

- Polishing

- Pad printing

- Silk screening

- Custom color painting

- Laser finishing

- Heat staking

Rapid Mold Tooling:

Short run plastic injection molding, typically from 50 to 100,000 pieces. Tool steel used: Aluminum 7075, P20, 718H and NAK-80

Production Mold Tooling

Larger production volumes, from 100,000 to millions of injection molded parts. For abrasive, corrosive, and engineering-grade plastics, we will use fully-hardened tool steel such as H13 and S136.